View larger

View larger PPS Filter Bag

Our PPS filter bag has unique flame retardant property, extraordinary heat-resistance, chemical and anti-radiation and electrical insulation property.

Detail

Manufacture Process

Filter Application

Packing & Delivery

Technical Data

How to Order?

PPS Filter Bag Details

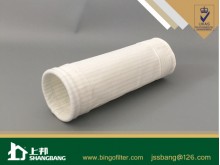

Fabric: PPS fiber (polyphenylene sulfide)

Temperature resistance: up to 160℃

Area weight (g/m2): 350~700

Thickness (mm): 1.2~2.4

Filtration precision: ≤30mg/nm3

Working lifetime: 8000 hours and more

Diameter & Length: No limited

PPS Filter Bag Surface treatment

Water and oil repellent treatment: A substantial increase in performance of water and oil repellent

- Acrylic coating: A substantial increase in Abrasion resistance property

- Carbon coating: Anti-spark

- PTFE film: Improve filtration precision: ≤5gsm/Nm3, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

- PTFE paint-coating: Improve filtration precision: ≤10gsm/Nm3, does not lower the filtration efficiency; and a substantial increase in acid-base resistance property

- PTFE dipping: Improve filtration precision: ≤25gsm/Nm3, does not lower the filtration efficiency; and a small increase in acid-base resistance property

- Our imported high tech fully automatic PPS filter bag production line, which guaranteed production efficiency, felt quality and lowered product cost

PPS Filter Bag Features

- PPS fiber does not burn, and it does not support burning neither

- Resistance to oxidation is poor. So the working environment requires the oxygen content less than 14%(Vol.), and the oxynitride content is less than 600mg/Nm3.

- Optional process: coatings, finishes, sizes and configurations.

- Optional choice: fabric weights and treatments such as singed, glazed, PTFE, anti-static, fire-retardant, oleo-phobic, acid resistant and more.

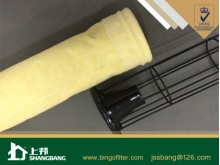

- Configurations (bag construction): snap band top, A-hanger, raw edge, grommet, cord, loop, strap, disc bottom, disc wear-strip, flange, hem, sewn flat, envelope, compression cap, and more.

PPS Filter Bag Application:

- Minerals Processing: Cement kiln/mill, alkali bypass, lime kiln, and lightweight aggregate dust collectors

- Metals Processing: Iron cupola

- Power Generation and Incineration: Soil remediation

Packing&Delivery&Payment

- packing can be customized, normally we pack pps filter bag by polybag

2. ETD: 10-15 days after receiving your deposit;

3. Payment terms: 30% deposit, balance against copy of documents;

4. Payment can be made by L/C,T/T;

Payment | Order Amount(USD) |

100%TT | <5000 |

50% Deposit the balance 50% will be against the copy of B/L | 5000-10000 |

30% Deposit the balance 70%will be against the copy of B/L | >10000 |

PPS Filter Bag Specification

| Weight: | 500~600g | |

| Fiber Content: | PPS fiber (polyphenylene sulfide) | |

| Fabric Construction: | Double Face Filling | |

| Continuous Operating Temperature: | 160°C | |

| Maximum Surge Temperature: | 190°C | |

| Acid Resistance: | Good | |

| Alkali Resistance: | Good | |

| Breaking Strength | ||

| • | Warp: | 1200 N/2.54 cm |

| • | Fill: | 1300 N/2.54 cm |

| Thickness (mm) | 1.2~2.4 | |

| Durability: | 8000 hours and more | |

How to business with us?

1. What you need to do?

You just need to tell us your all your working conditions in through details:

- Size, material you want;

- The former filters you use;

- Your working conditions;

All the next jobs will be done by us:

2. What we offer?

- Quick response

- Quick delivery& Competitive price& stable fine quality

- Professional technical and commercial suggestions provided by experienced staff.

- Custom-made design

- Free samples is accepted if you write to us.

- The filtration accuracy and efficiency you want to achieve;

- Meet clients demand for controlling dust emission

- Meet clients’ expectation of long working life

- Meet requirement for high cost performance

We are passionate about what we do and we do things right. Contact us

14 other products in the same category:

DUST COLLECTOR BAG

New products

-

Snap ring for bag filter

Our snap rings are manufactured to the highest standards. All production...

-

Snap band for filter bags

Snap band type filter bags are the most popular one among all the filter...

-

Liquid micron Polyester filter bag

Boing liquid micron Polyester filter bag is a main stay in many...

-

Glass fiber filter bag

Glass fiber filter bag is widely used in steel & metallurgy &...

-

Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy &...

Viewed products

-

PPS Filter Bag

Our PPS filter bag has unique flame...