View larger

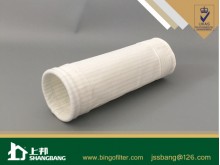

View larger FMS Filter Bag

A 220°C maximum service temperature, FMS filter bag is a conventional filter material especially for cement plants and steel & iron industry.

Detail

Manufacture Process

Filter Application

Technical Data

Surfance Treatment

How to Order?

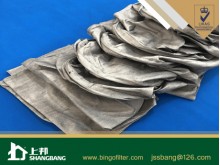

FMS filter bag material is a special composite material. FMS fumes needle punched felt is made of differnt fibers, like P84 fibers, fiberglass fibers, Nomex fibers, PPS fibers. Normally manufacturers all use fiberglass scrim.

But some suppliers mix polyester fibers into the felt, and different FMS manufacturers use different proportion, so the price also differes a lot. It also means to choose an honest manufacture is very important. Boing filter welcomes friend from all over the world.

- Our imported high tech fully automatic FMS Filter Bag production line, which guaranteed production efficiency, felt quality and lowered product cost

- We can glue on the 3 lines stitching at the same time to make sure 10mg emission for FMS filter bags

- We can produce FMS needle punched felts according to your own proportion to save cost and meet the best efficiency

FMS Filter Bag Features

- Unique acid-resistant treatment reduces the detrimental effects of moisture and acids

- Good performances of intensity. Good abrasion and folding resistance.

- More options for coatings, finishes, sizes and configurations.

- More choice for singed, glazed, PTFE, anti-static, fire-retardant, oleo-phobic, acid resistant

- More choice for constructions snap band top, A-hanger, raw edge, grommet, cord, loop, strap, disc bottom, disc wear-strip, flange, hem, sewn flat, envelope, compression cap, and more.

APPLICATIONS for FMS Filter Bag

- Chemicals Processing: Dryer baghouses in the pigment, plastic, and catalyst industries.

- Minerals Processing: Dryer baghouses in the gypsum industry and clinker cooler baghouses.

- Metals Processing: High temperature process collectors for lead oxide and electric arc furnace baghouses in the steel industry

- Power Generation and Incineration: Fly ash handling collectors

Technical Data for FMS Filter Bag

| Weight: | 950 g/m2 | |

| Fiber Content: | 25% chemical fiber & 10% p84 & 65%fiberglass | |

| Felt Construction: | fiberglass | |

| Continuous Operating Temperature: | 220°C (400°F) | |

| Maximum Surge Temperature: | 240°C (425°F) | |

| Acid Resistance: | Good | |

| Alkali Resistance: | Good | |

| Breaking Strength | ||

| • | Warp: | 2100 N/5 cm |

| • | Fill: | 2200 N/5 cm |

| Mullen Burst: | 4653 kPa (675 psi) | |

| Thickness: | 2.2~2.4 | |

| Elongation at 50 lb | ||

| • | Warp: | 2.00% |

| • | Fill: | 5.50% |

| Flame-Resistance Testing ASTMD 6413-08: | ||

| • | After Flame | 0 seconds |

| • | After Glow | 35.1 seconds |

| • | Char Length | 1.1 inches |

| Working lifetime | 30000 hours and more | |

Surface treatment for FMS Filter Bag

Water and oil repellent treatment: A substantial increase in performance of water and oil repellent

- Carbon coating: Anti-spark

- PTFE film: Improve filtration precision: ≤5gsm/Nm3, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

- PTFE membrane: Improve filtration precision: ≤10gsm/Nm3, does not lower the filtration efficiency; and a substantial increase in acid-base resistance property

- PTFE dipping: Improve filtration precision: ≤25gsm/Nm3, does not lower the filtration efficiency; and a small increase in acid-base resistance property

How to business with us?

1. What you need to do?

You just need to tell us your all your working conditions in through details:

- Size, material you want; or do you have special requirements for FMS filter bags?

- The former filter bags you use;

- Your current working conditions;

All the next jobs will be done by us:

2. What we offer?

- Quick response, including offer, cost down in details, drawings, professional filtration solutions

- Quick delivery& Competitive price& stable fine quality

- Professional technical and commercial suggestions provided by experienced staff.

- Custom-made design

- Free samples is accepted if you inquire.

- The filtration accuracy and efficiency you want to achieve;

- Meet clients demand for controlling dust emission

- Meet clients’ expectation of long working life

- Meet requirement for high cost performance

We are passionate about what we do and we do things right. Contact us, let us help you choose the most economical FMS filter bags for your application.

14 other products in the same category:

DUST COLLECTOR BAG

New products

-

Snap ring for bag filter

Our snap rings are manufactured to the highest standards. All production...

-

Snap band for filter bags

Snap band type filter bags are the most popular one among all the filter...

-

Liquid micron Polyester filter bag

Boing liquid micron Polyester filter bag is a main stay in many...

-

Glass fiber filter bag

Glass fiber filter bag is widely used in steel & metallurgy &...

-

Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy &...

Viewed products

-

FMS Filter Bag

A 220°C maximum service temperature,...