View larger

View larger Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy & alloy industry. Fiberglass filter bags can reach a maxxium temperature of 260℃ in reverse pulse jet bag filters. Our fiberlass filter bag can work for 2 years without replacement.

Detail

Manufacture Process

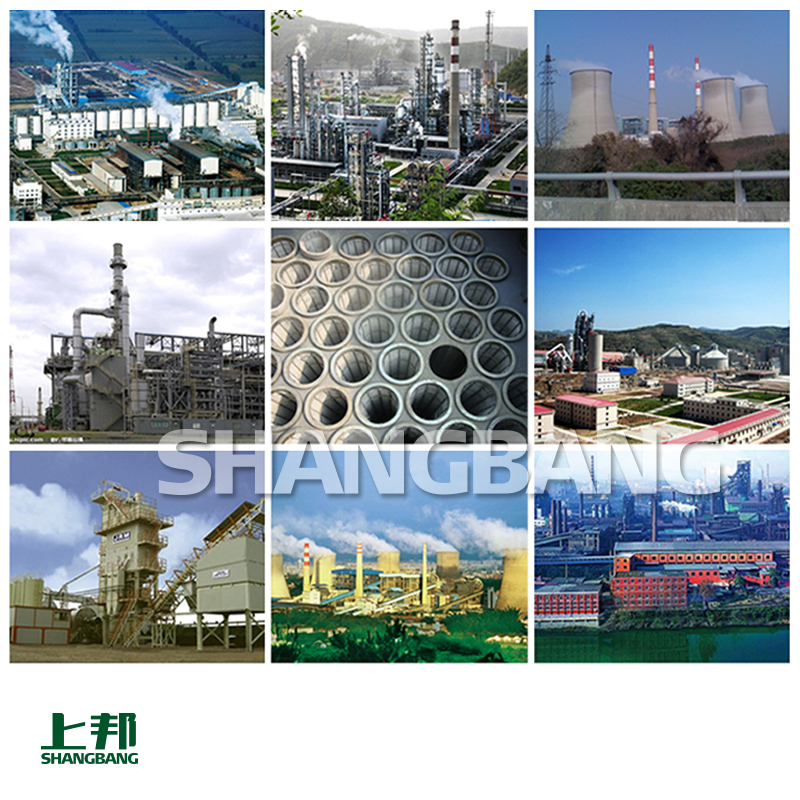

Filter Application

Technical Data

Surfance Treatment

How to Order?

Fiberglass filter bags we made but not just these

Anti-spark Filter Bag |

Fiberglass filter bag Shape:

1. the fiberlass filter bags can be normal shape, with snap ring and round bottom; most sizes like 160*6000, 130*3000, with SGT fiberlass fabric

2. big fiberglass filter bag, with two open ends; most sizes like 300*10000mm, with 6 pcs steel rings or without

- Our imported high tech fully automatic production line, which guaranteed fiberglass filter bags production efficiency, fiberglass fabric quality and lowered product cost

Fiberglass filter bag applications

- Minerals Processing: Dryer baghouses in the gypsum industry and clinker cooler baghouses.

- Metals Processing: High temperature process collectors for lead oxide and electric arc furnace baghouses in the steel industry

Fiberglass filter bags parameter

| Weight: | 500-750 g/m2 | |

| Fiber Content: | 100% fiberglass | |

| Felt Construction: | fiberglass | |

| Continuous Operating Temperature: | 260°C | |

| Maximum Surge Temperature: | 280°C | |

| Acid Resistance: | Good | |

| Alkali Resistance: | Good | |

| Breaking Strength | ||

| • | Warp: | 2000 N/5 cm |

| • | Fill: | 2000 N/5 cm |

| Mullen Burst: | 4653 kPa (675 psi) | |

| Thickness: | 0.8 | |

| Elongation at 50 lb | ||

| • | Warp: | 2.00% |

| • | Fill: | 5.50% |

| Flame-Resistance Testing ASTMD 6413-08: | ||

| • | After Flame | 0 seconds |

| • | After Glow | 35.1 seconds |

| • | Char Length | 1.1 inches |

| Working lifetime | 8000 hours and more | |

Fiberglass filter bag surface treatment

1. PTFE membrane/laminated;

2. PTFE impregating;

3. SGT(Silicon and graphite treatment)

4. Acid-Resistant Treatment

5. Alkali-Resistant Treatment

How to business with us?

1. What you need to do?

You just need to tell us your all your working conditions in through details:

- Size, material you want;

- The former filters you use;

- Your working conditions;

All the next jobs will be done by us:

2. What we offer?

- Quick response

- Quick delivery& Competitive price& stable fine quality

- Professional technical and commercial suggestions provided by experienced staff.

- Custom-made design

- Free samples is accepted if you write to us.

- The filtration accuracy and efficiency you want to achieve;

- Meet clients demand for controlling dust emission

- Meet clients’ expectation of long working life

- Meet requirement for high cost performance

We are passionate about what we do and we do things right. Contact us!

14 other products in the same category:

DUST COLLECTOR BAG

New products

-

Snap ring for bag filter

Our snap rings are manufactured to the highest standards. All production...

-

Snap band for filter bags

Snap band type filter bags are the most popular one among all the filter...

-

Liquid micron Polyester filter bag

Boing liquid micron Polyester filter bag is a main stay in many...

-

Glass fiber filter bag

Glass fiber filter bag is widely used in steel & metallurgy &...

-

Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy &...

Viewed products

-

Fiberglass filter bag

Fiberglass filter bag is widely used...