View larger

View larger PTFE Filter Bag

PTFE filter bag is one of the best filter medias among all the non-woven felt filter bags, it can also be called teflon filter bags; it's a high grade product of filter bag. PTFE filter bag has the best chemical resistance property. Due to its PTFE membrane, it has a very good filtration efficiency. Its working life can reach 5 years in the normal working condition.

Detail

Manufacture Process

Filter Application

Packing & Delivery

Technical Data

How to Order?

PTFE Filter Bag Details

Fabric: 100% PTFE fiber

Temperature resistance: up to 260℃ (392℉)

Area weight (g/m2): 750-800

Thickness (mm): 1.2~1.5

Filtration precision: ≤5mg/nm3

Working lifetime: 8000 hours and more

Diameter & Length: No limited, can be customzied

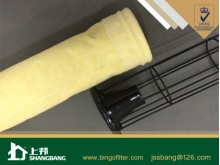

- Our imported high tech fully automatic production line, which guaranteed PTFE filter bag production efficiency, felt quality and lowered product cost

- We have also equipped with PTFE fiber production line, and PTFE needle pucnhed felt production, together with PTFE scrim production machine. Therefore, from all the production process, we can control the PTFE filter bags quality well and control the cost in the same way

- Boing filter is one of the very few factories in China that we can produce PTFE staple fibers

- Welcome friends to visit our PTFE fiber and PTFE filter bags production workshop

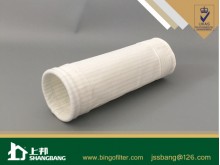

PTFE Filter Bag Surface Treatment

There are 2 kinds of treatment : "PTFE film", also called PTFE membrane and "PTFE dipping"

PTFE film/membrane: Improve filtration precision: ≤5gsm/Nm3, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

PTFE dipping: Improve filtration precision: ≤25gsm/Nm3, does not lower the filtration efficiency; and a small increase in acid-base resistance property

PTFE Filter Bag Features

1. Excellent temperature resistance: up to 260℃ (572℉)

2. Extremely long working life. Service life can reach 6 years at the temperature 66℃~240℃ and normal working conditions.

3. Excellent performance of anti-acid and anti-alkali resistance

4. Excellent filter efficiency

5. Good performances of hydrolysis stability and flame retardant

6. Suitable using on various power plant boiler and waste incineration boiler. The weakness is poor folding property and higher price.

7. Available in various fabric weights and treatments such as singed, glazed, PTFE, anti-static, fire-retardant, oleo-phobic, acid resistant and more.

8. Configurations (bag construction) include snap band top, A-hanger, raw edge, grommet, cord, loop, strap, disc bottom, disc wear-strip, flange, hem, sewn flat, envelope, compression cap, and more.

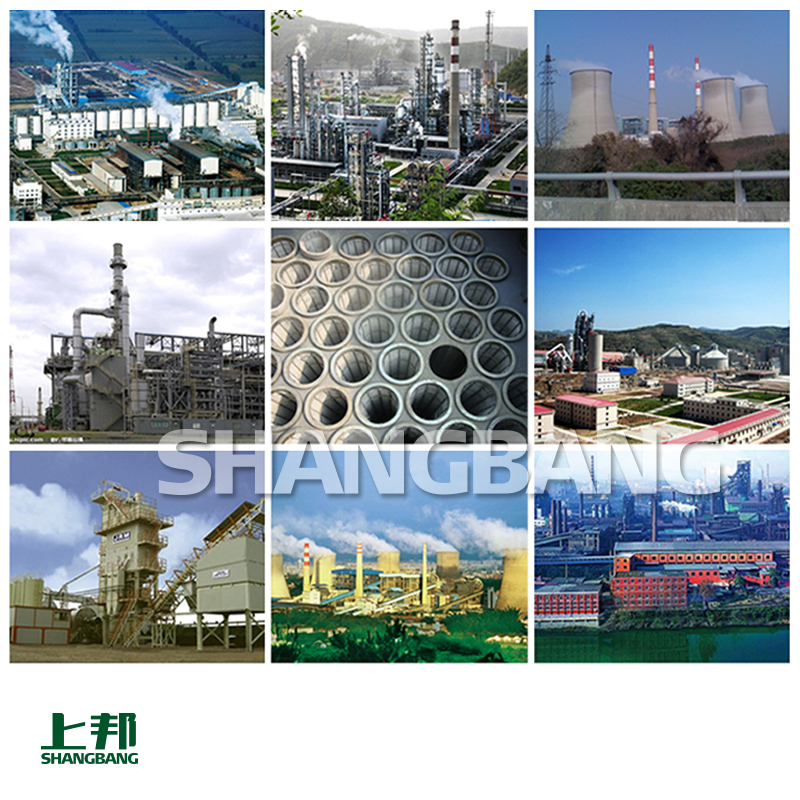

PTFE Filter Bag APPLICATIONS

1. Power Generation and Incineration: Medical, municipal, industrial, sewage sludge, biomass, and hospital waste incineration, as well as coal-fired boilers.

2. Chemicals Processing: Dryer offgas filtration under chemi-cally or thermally demanding conditions.

3. Minerals Industry: Brick and light-weight aggregate kilns.

Packing&Delivery&Payment

1. Packing can be customized, normally we pack ptfe filter bag by carton;

2. ETD: 10-15 days after receiving your deposit;

3. Payment terms: 30% deposit, balance against copy of documents;

4. Payment can be made by L/C,T/T;

Payment | Order Amount(USD) |

100%TT | <5000 |

50% Deposit the balance 50% will be against the copy of B/L | 5000-10000 |

30% Deposit the balance 70%will be against the copy of B/L | >10000 |

5. MOQ: 500pcs for PTFE filter bags

6. Transportation: We can recommend the most economic way of logistics, including maritime, land, air and other ways, designated forwarder also accepted.

Technical Data for PTFE Filter Bag

| Weight | 700~800 g/m2 | |

| Fiber Content: | Staple – Expanded PTFE fibers (Polytetrafluoroethylene) | |

| Scrim – Woven Expanded PTFE(210GSM) | ||

| Felt Construction: | Supported Needle punched felt | |

| Continuous Operating Temperature: | 260°C | |

| Maximum Surge Temperature: | 270°C | |

| Acid Resistiance: | Excellent | |

| Alkali Resistance: | Excellent | |

| Breaking Strength | ||

| • | Warp: | 1000 N/5 cm |

| • | Fill: | 1100 N/5 cm |

| Mullen Burst: | 2758 kPa (400 psi) min | |

| Thickness: | 1.2~2.4 | |

| Thermal Stability: | < 2% shrinkage at 260°C (500°F) after 2 hours (unrestrained) | |

| Durability: | 12000 hours and more | |

How to business with us?

1. What you need to do?

You just need to tell us your all your working conditions in through details:

- Size, material you want;

- The former filters you use;Why you want to change to PTFE filter bags?

- Your current working conditions;

All the next jobs will be done by us. Boing engineers will give you a professional filtration solution.

2. What we offer?

- Quick response

- Quick delivery& Competitive price& stable fine quality

- Professional technical and commercial suggestions provided by experienced staff.

- Custom-made design

- Free samples is accepted if you write to us.

- The filtration accuracy and efficiency you want to achieve;

- Meet clients demand for controlling dust emission

- Meet clients’ expectation of long working life

- Meet requirement for high cost performance of the filter medias.

We are passionate about what we do and we do things right. Contact us!

14 other products in the same category:

DUST COLLECTOR BAG

New products

-

Snap ring for bag filter

Our snap rings are manufactured to the highest standards. All production...

-

Snap band for filter bags

Snap band type filter bags are the most popular one among all the filter...

-

Liquid micron Polyester filter bag

Boing liquid micron Polyester filter bag is a main stay in many...

-

Glass fiber filter bag

Glass fiber filter bag is widely used in steel & metallurgy &...

-

Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy &...

Viewed products

-

PTFE Filter Bag

PTFE filter bag is one of the best...