View larger

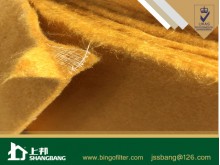

View larger Nonwoven Aramid(Nomex) Needle punched Felt

Nonwoven Aramid(Nomex) Needle punched Felt is the most popular heat-resistance felts.

Detail

Manufacture Process

Filter Application

Packing & Delivery

Technical Data

How to Order?

Nonwoven Aramid(Nomex) Needle punched Felt Description

Capacity: 5000 m2/day

Service life: More than 3000 hours

Aramid Needle Felt is not flammable nor ignition, suitable for high temperature environment.

Tips: People call the Aramid Needle Felt as Nomex. In fact the "Nomex ®" is a registered trademark belongs to DuPont ®.

Our imported high tech fully automatic production line, which guaranteed production efficiency, felt quality and lowered product cost for needle felt

Packing&Delivery&Payment for Nonwoven Aramid(Nomex) Needle punched Felt

1. Packing can be customized, normally we pack by polybag

2. ETD: 10-15 days after receiving your deposit;

3. Payment terms: 30% deposit, balance against copy of documents;

Payment can be made by L/C,T/T;

Payment | Order Amount(USD) |

100%TT | <5000 |

50% Deposit the balance 50% will be against the copy of B/L | 5000-10000 |

30% Deposit the balance 70%will be against the copy of B/L | >10000 |

4. MOQ: 500㎡

5. Transportation: We can recommend the most economic way of logistics, including maritime, land, air and other ways, designated forwarder also accepted.

Technical Data for Nonwoven Aramid(Nomex) Needle punched Felt

Material : | 100% Aramid staple fiber | |

Scrim: | with Aramid staple yarn | |

Width: | ≤2.2m | |

Thickness: | 1.2-2.2mm | |

Weight: | 300 -650g/m2 ±10% | |

Heat-resistance (°C/°F): | Continue: 204/399.2, | |

Instant: 240/464 | ||

Good resistance for the chemical corrosion: | Anti acid and alkali, hardly corrosion. | |

Variety of finish treatments: | Water&Oil proof, PTFE Membrane, PTFE Impregnation | |

Fire retardant property: | Carbonization up to 400°C/752°F, no spontaneous or natural combustion. | |

High stability of dimension : | Only 1 percent flexibility at 230 °C/446°F, with excellent high temperature stability. | |

Weight(gsm) | 500 | |

Thickness(mm) | 1.8 | |

Width(mm) | ≤2.2m | |

Finish treatment | Singeing, Calendering, Heat setting | |

Air permeability(L/m2.s) | 200-300 |

|

Tensile strength(N/5cm) | warp | ≥1000 |

weft | ≥1100 | |

Tensile elongation(%) | warp | ≤20 |

weft | ≤30 | |

Heat shrinkage(%) | warp | ≤1.5 |

weft | ≤1.0 | |

Temperature(°C/°F) | Continue | 204/399.2 |

Instant | 240/464 | |

Anti-acid | Good | |

Anti-alkali | Good | |

Anti-abrasion | Excellent | |

hydrolysis stability | Fair | |

How to business with us?

1. What you need to do?

You just need to tell us your all your working conditions in through details:

- Size, material you want;

- The former filters you use;

- Your working conditions;

All the next jobs will be done by us:

2. What we offer?

- Quick response

- Quick delivery& Competitive price& stable fine quality

- Professional technical and commercial suggestions provided by experienced staff.

- Custom-made design

- Free samples is accepted if you write to us.

- The filtration accuracy and efficiency you want to achieve;

- Meet clients demand for controlling dust emission

- Meet clients’ expectation of long working life

- Meet requirement for high cost performance

We are passionate about what we do and we do things right. Contact us, let us help you choose the most economical filter felt for your application.

11 other products in the same category:

NEEDLE PUNCHED FELTS

New products

-

Snap ring for bag filter

Our snap rings are manufactured to the highest standards. All production...

-

Snap band for filter bags

Snap band type filter bags are the most popular one among all the filter...

-

Liquid micron Polyester filter bag

Boing liquid micron Polyester filter bag is a main stay in many...

-

Glass fiber filter bag

Glass fiber filter bag is widely used in steel & metallurgy &...

-

Fiberglass filter bag

Fiberglass filter bag is widely used in steel & metallurgy &...

Viewed products

-

Nonwoven Aramid(Nomex)...

Nonwoven Aramid(Nomex) Needle punched...